Product Categories

- > Digital Textile Printer

-

- Fedar Sublimation Textile Printer

FEDAR FD61916E Sublimation Printer FEDAR FD1924 Sublimation Printer FEDAR FD1912S Sublimation Printer FEDAR FD61915E-A Sublimation Printer FEDAR FD5198E Sublimation Printer FEDAR FD51915E Sublimation Printer FEDAR FD53215E Sublimation Printer FEDAR FD61915E Sublimation Printer FD6198E 8 Heads Printer FD6194E 4 Heads Printer FD5194E 4 Heads Printer FD5328E 3.2m Printer FD5193E 3 Heads Printer Fedar TC Series Sublimation Printer(3heads,4heads,6heads)(Stop) FD5268E 2.6m Printer FD5223E 2.2m Printer (Stop) FD1900 2 Heads Printer AL193 3 Heads Printer (Stop) TC1932 2 Heads Printer (Stop)

- Fedar Direct To Film

A3 DTF Printer FDA3 DTF Printer FD70-5 DTF Printer FD70-3 DTF Printer (Stop) FD30 DTF Printer (Stop) FD60 DTF Printer FD70-4 DTF Printer FD65-2 DTF Printer (Stop) FD70-2 DTF Printer (Stop) TR 4180 (Stop) FD 680 DTG (Stop) FD1828 Belt cotton printer (Stop)

- Fedar Sublimation Textile Printer

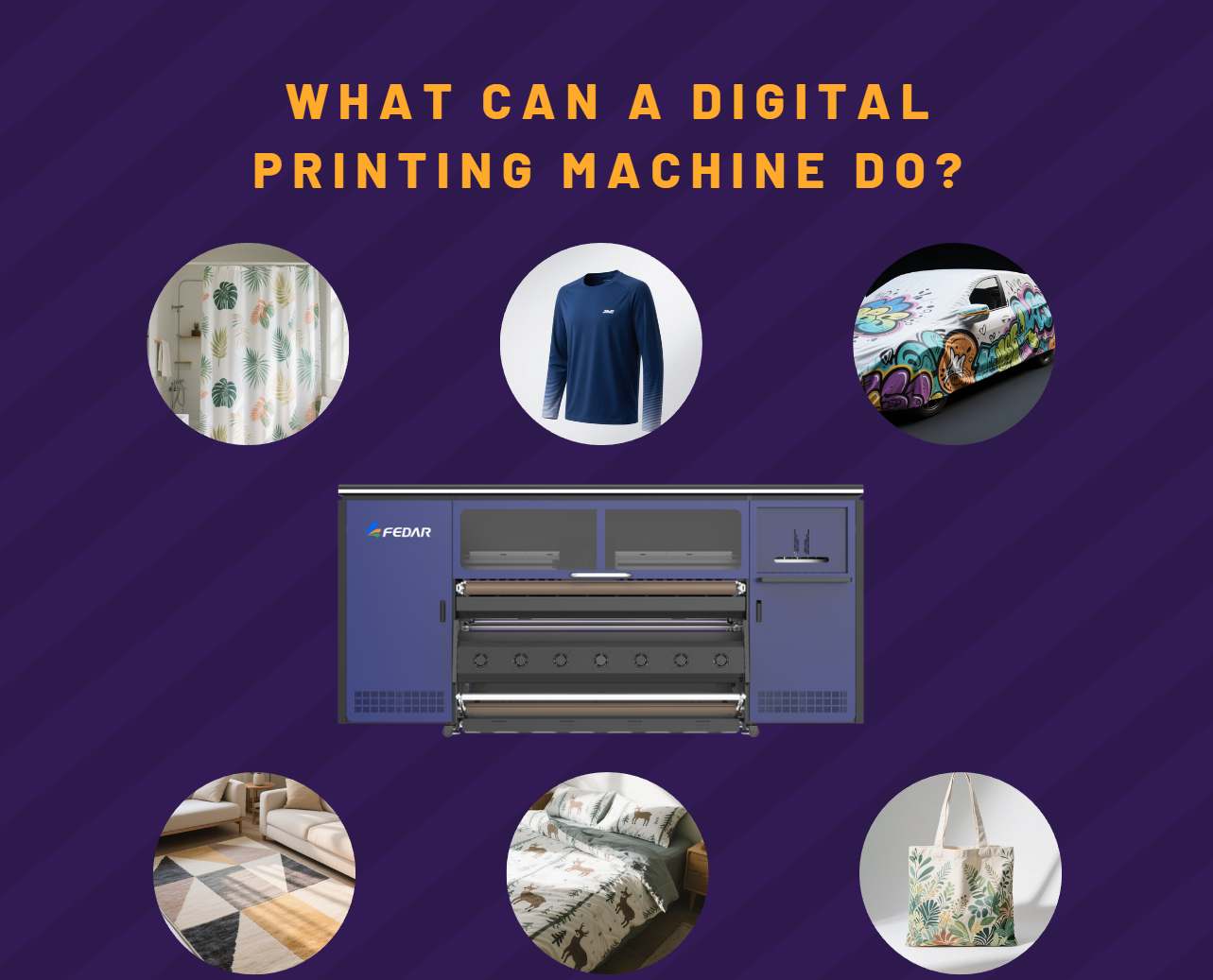

When you have a digital printing machine, what can you do with it?

2025-08-26Digital printing technology is increasingly popular due to its advantages such as high printing precision, no need for plate making, flexible batch production, environmental friendliness, and small footprint. Nowadays, various new types of digital printing machines have emerged, and the development of digital printing technology is showing a trend of numerous players rising and a hundred flowers blooming.

Today, let’s talk about which fields digital printing machines can be applied to.

Fedar digital printing machines employ the thermal transfer printing process.

First, let’s look at how it works:

Thermal transfer printing is a commonly used method in textile printing. It involves inputting digitally created and processed patterns into a computer, then using an output printing system (digital printing machine) to print specialized ink onto transfer paper. The design is then transferred onto the fabric using transfer equipment (such as a heat press machine). Utilizing the sublimation properties of disperse dyes, the dyes are transferred and fixed onto synthetic fibers like polyester under high temperatures.

Main advantages of the thermal transfer digital printing process:

This printing technology integrates green, eco-friendly, low-carbon, energy-saving, emission-reducing, and ecological features, representing a major breakthrough in textile printing technology. The printed fabric features a soft hand feel, bright colors, rich layers, and good breathability.

The thermal transfer process allows for pre-inspection of the transfer paper before printing on the fabric. Any issues such as misalignment or color bleeding can be detected and rejected in advance. As a result, garments and other fabrics printed using the thermal transfer process rarely have defective prints.

Digital printing production truly enables small-batch, rapid-response manufacturing, with printing starting from just one piece and no restrictions on production volume.

Application Fields

Not all products can be printed using thermal transfer, as it depends on factors such as heat resistance and smoothness. However, with continuous technological advancements, products that have been successfully developed using thermal transfer technology include:

NO.1

Apparel: T-shirts, sportswear, couples' wear, swimwear, shoes, hats, and other personalized clothing.

NO.2

Home textiles: Curtains, shower curtains, carpets, sofa cushions, sofa covers, tablecloths, cooling mats, beddings, pillowcases, etc.

NO.3

Bags and luggage: Suitcases, canvas bags, backpacks, chest bags, etc.

NO.4

Personalized customization: Advertising displays, flags, tents, car covers, mouse pads, coasters, etc.

Thermal transfer digital printing is mostly applied in the textile printing market and is suitable for polyester-based fabrics primarily made of chemical fibers.

As a comprehensive digital textile printing solution provider integrating pre-sales consultation, in-sales debugging, after-sales service, and software support, Fedar Textile Printing develops each product based on corresponding market demands. To cater to different industries, Fedar has launched multiple models with various widths, including 1.9 meters, 2.2 meters, 2.6 meters, 3.2 meters, and 4.2 meters, to meet diverse printing needs.