Product Categories

- > Digital Textile Printer

-

- Fedar Sublimation Textile Printer

FEDAR FD61916E Sublimation Printer FEDAR FD1924 Sublimation Printer FEDAR FD1912S Sublimation Printer FEDAR FD61915E-A Sublimation Printer FEDAR FD5198E Sublimation Printer FEDAR FD51915E Sublimation Printer FEDAR FD53215E Sublimation Printer FEDAR FD61915E Sublimation Printer FD6198E 8 Heads Printer FD6194E 4 Heads Printer FD5194E 4 Heads Printer FD5328E 3.2m Printer FD5193E 3 Heads Printer Fedar TC Series Sublimation Printer(3heads,4heads,6heads)(Stop) FD5268E 2.6m Printer FD5223E 2.2m Printer (Stop) FD1900 2 Heads Printer AL193 3 Heads Printer (Stop) TC1932 2 Heads Printer (Stop)

- Fedar Direct To Film

FD1808 DTF Printer FDA3 Pro DTF Printer A3 DTF Printer FDA3 DTF Printer FD70-5 DTF Printer FD70-3 DTF Printer (Stop) FD30 DTF Printer (Stop) FD60 DTF Printer FD70-4 DTF Printer FD65-2 DTF Printer (Stop) FD70-2 DTF Printer (Stop) TR 4180 (Stop) FD 680 DTG (Stop) FD1828 Belt cotton printer (Stop)

- Fedar Sublimation Textile Printer

The Essential Guide to DTF Hot Melt Powder for Perfect Transfers

2026-01-16What is DTF Hot Melt Powder?

DTF Hot Melt Powder is a thermoplastic adhesive, applied as a fine dust to the wet ink printed on a PET film. After printing with a white underbase and colors, the powder is evenly distributed using a powder shaker or manually. When this powdered film passes through a heat press, the powder melts, creating a strong, flexible adhesive layer that permanently bonds the design to the garment upon cooling. Without this powder, the DTF transfer process cannot be completed successfully.

Key Properties of Quality DTF Powder

A superior DTF powder, like those compatible with a Fedar DTF printer system, offers a suite of essential properties for professional results:

Temperature Resistance: Performs consistently in a wide range, ensuring stability during the hot-press transfer and throughout the garment's life.

Chemical Stability: Resistant to water, acids, alkalis, and corrosion (oxidants, oils), preserving the print's integrity.

Soft Hand Feel: When melted and cured correctly, it creates a flexible adhesive layer that maintains the fabric's drape and comfort.

Choosing the Right Powder for Your Project

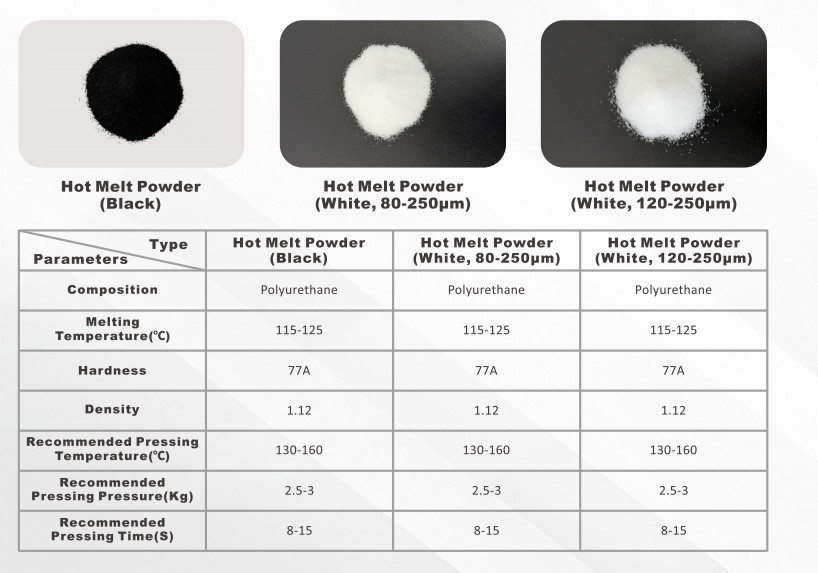

Selecting the correct powder type is as important as using a reliable Fedar DTF printer. Powders are categorized by particle size and specialized additives to match different fabrics and effects:

Soft Powder (80-170μm): Ideal for smooth fabrics like T-shirts and polos, providing a soft, seamless finish.

Coarse Powder (120-250μm): Designed for textured materials like denim, canvas, or linen, offering a stronger bond for rougher surfaces.

Anti-Stretch Powder: Formulated for elastic fabrics, maintaining adhesion and preventing cracks on stretchy materials.

Anti-Sublimation Powder: Essential for dark garments, it acts as a blocker to prevent the underlying fabric color or pattern from showing through the transfer.

Quick-Peel Powder: Enables immediate peeling of the film after pressing (hot peel), significantly speeding up production workflow.

Storage and Best Practices

To maintain performance, DTF powder must be stored in a sealed container in a cool, dry environment. Exposure to humidity causes clumping, leading to uneven application, poor adhesion, and flawed transfers—issues that can undermine the quality output of even the best Fedar DTF printer.

Conclusion: The Foundation for Professional Results