Product Categories

- > Digital Textile Printer

-

- Fedar Sublimation Textile Printer

FEDAR FD61916E Sublimation Printer FEDAR FD1924 Sublimation Printer FEDAR FD1912S Sublimation Printer FEDAR FD61915E-A Sublimation Printer FEDAR FD5198E Sublimation Printer FEDAR FD51915E Sublimation Printer FEDAR FD53215E Sublimation Printer FEDAR FD61915E Sublimation Printer FD6198E 8 Heads Printer FD6194E 4 Heads Printer FD5194E 4 Heads Printer FD5328E 3.2m Printer FD5193E 3 Heads Printer Fedar TC Series Sublimation Printer(3heads,4heads,6heads)(Stop) FD5268E 2.6m Printer FD5223E 2.2m Printer (Stop) FD1900 2 Heads Printer AL193 3 Heads Printer (Stop) TC1932 2 Heads Printer (Stop)

- Fedar Direct To Film

FD1808 DTF Printer FDA3 Pro DTF Printer A3 DTF Printer FDA3 DTF Printer FD70-5 DTF Printer FD70-3 DTF Printer (Stop) FD30 DTF Printer (Stop) FD60 DTF Printer FD70-4 DTF Printer FD65-2 DTF Printer (Stop) FD70-2 DTF Printer (Stop) TR 4180 (Stop) FD 680 DTG (Stop) FD1828 Belt cotton printer (Stop)

- Fedar Sublimation Textile Printer

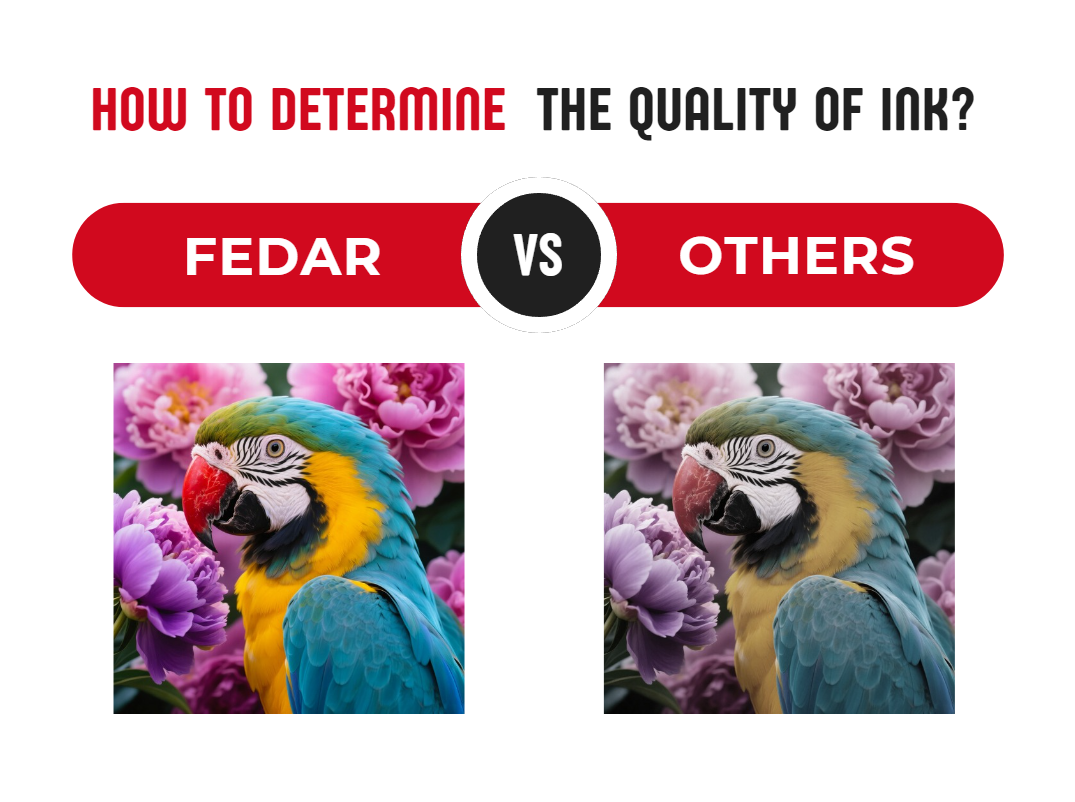

The Definitive Guide to Evaluating Ink Quality for Professional Textile Printing

2025-12-05

1. Assess Core Performance Metrics

True ink quality is revealed through measurable outcomes. A high-grade ink should excel in the following areas:

Opacity and Color Fidelity: Superior white ink, for instance, must have strong hiding power and high whiteness to provide a brilliant base for colors on dark garments, ensuring vibrant contrast. Overall ink should deliver high color density with minimal unwanted "whitening" for consistently vivid final results.

Fastness and Durability: The ink must meet or exceed industry standards for color fastness. This includes excellent resistance to dry/wet rubbing (level 4-5), washing (level 4-5), and perspiration to ensure prints last.

Operational Fluency: For mass production, ink must have excellent fluency. This prevents clogging in the printheads of your Fedar textile printer, ensuring uninterrupted runs, consistent jetting, and high productivity.

2. Evaluate Physical and Compatibility Properties

Beyond print results, the physical behavior of the ink is crucial.

Compatibility: Quality ink exhibits excellent compatibility within its own series (e.g., between white and colored inks). This prevents undesirable color bleeding or penetration during printing, guaranteeing design integrity.

Substrate Feel: The final hand feel is paramount. Inks formulated with quality raw materials, such as specific imported and domestic blends, yield prints with good elasticity and a soft hand feel, enhancing the value of the finished textile product.

3. Scrutinize Composition and Safety

The foundation of ink quality lies in its formulation.

Raw Materials: Premium inks use high-purity, consistent raw materials from reputable suppliers. This ensures batch-to-batch stability and reliable performance in your Fedar sublimation printer.

Environmental & Safety Standards: A commitment to an environmentally friendly pigment formula is increasingly important. It reflects responsible manufacturing and ensures the final product is safer for both the end-user and the environment.

4. Trust in Brand and System Integration

For optimal results, especially with sophisticated equipment like a Fedar sublimation printer, using manufacturer-recommended or verified Fedar textile printer inks is advised. These inks are engineered and tested for perfect synergy with the printer's mechanics and software, ensuring all the above qualities are fully realized while protecting your printhead investment.

By applying this multi-faceted evaluation framework, you can make an informed decision, ensuring the inks you choose empower your business with reliability, stunning quality, and operational efficiency.