Product Categories

- > Digital Textile Printer

-

- Fedar Sublimation Textile Printer

FEDAR FD61916E Sublimation Printer FEDAR FD1924 Sublimation Printer FEDAR FD1912S Sublimation Printer FEDAR FD61915E-A Sublimation Printer FEDAR FD5198E Sublimation Printer FEDAR FD51915E Sublimation Printer FEDAR FD53215E Sublimation Printer FEDAR FD61915E Sublimation Printer FD6198E 8 Heads Printer FD6194E 4 Heads Printer FD5194E 4 Heads Printer FD5328E 3.2m Printer FD5193E 3 Heads Printer Fedar TC Series Sublimation Printer(3heads,4heads,6heads)(Stop) FD5268E 2.6m Printer FD5223E 2.2m Printer (Stop) FD1900 2 Heads Printer AL193 3 Heads Printer (Stop) TC1932 2 Heads Printer (Stop)

- Fedar DTF Printer

FD1808 DTF Printer FDA3 Pro DTF Printer A3 DTF Printer FDA3 DTF Printer FD70-5 DTF Printer FD70-3 DTF Printer (Stop) FD30 DTF Printer (Stop) FD60 DTF Printer FD70-4 DTF Printer FD65-2 DTF Printer (Stop) FD70-2 DTF Printer (Stop) TR 4180 (Stop) FD 680 DTG (Stop) FD1828 Belt cotton printer (Stop)

- Aulane DTF Printer

Aulane AL2808 DTF Printer Aulane AL2606 DTF Printer Aulane AL2604 DTF Printer Aulane AL2602 DTF Printer Aulane AL2302 DTF Printer Aulane AL2301 DTF Printer

- Fedar Sublimation Textile Printer

Print Without Compromise: The Triple-Heating System that Ensures Flawless Fedar Inkjet Printer Performance in Cold Weather

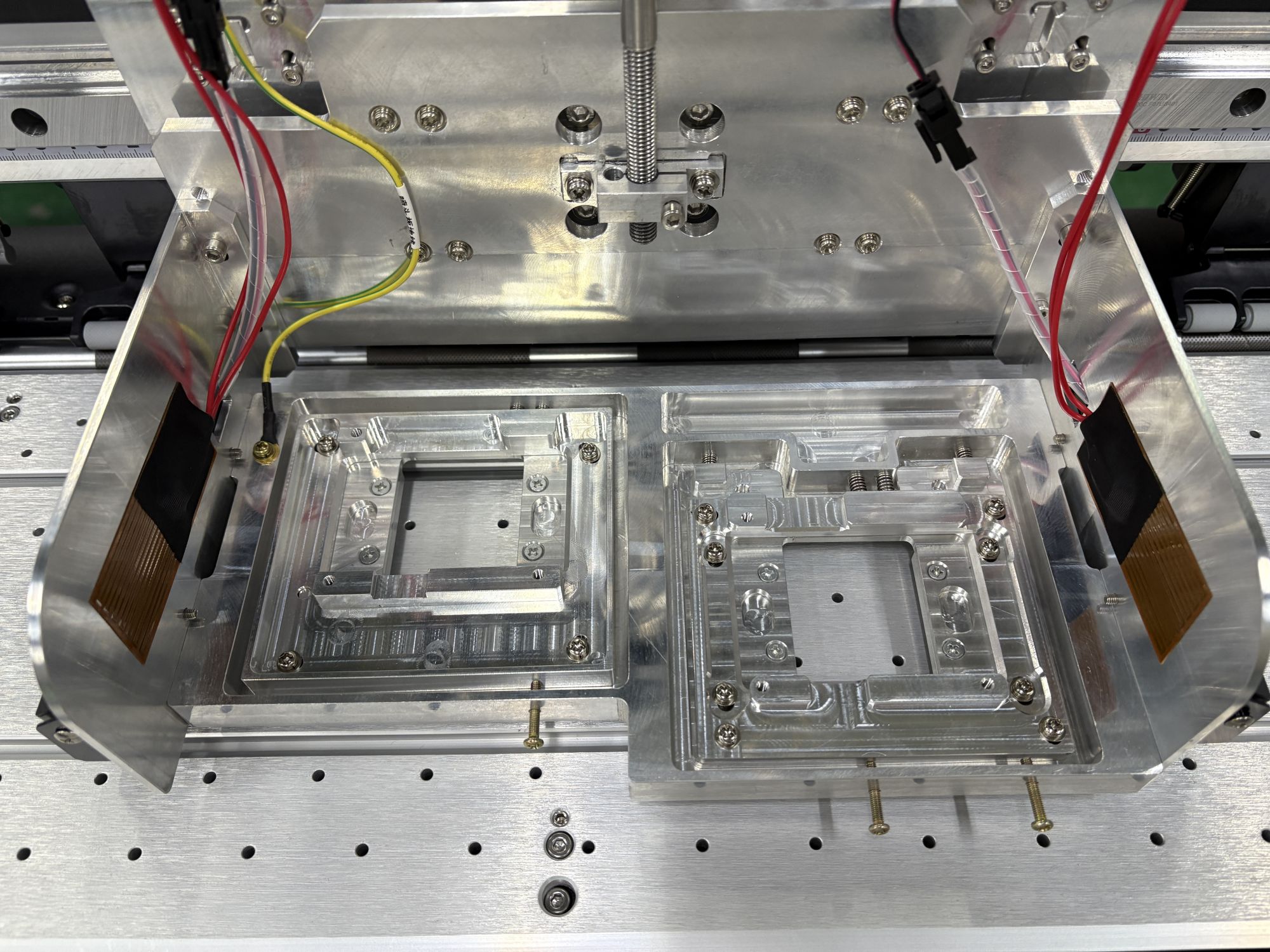

2026-01-221. Printhead Platen Heating: Precision at the Source

The foundation of cold-weather printing stability starts at the most critical component: the printhead. Fedar printers feature integrated printhead platen heating. This system maintains a stable, optimal temperature directly at the ink ejection point. By eliminating the temperature differential between the warm ink and a cold printhead environment, it effectively prevents common winter issues like ink viscosity fluctuation, nozzle clogging, and ink misting. The result? Every droplet is placed with precision, ensuring sharp lines, clean text, and perfect detail reproduction from the very first print of the day.

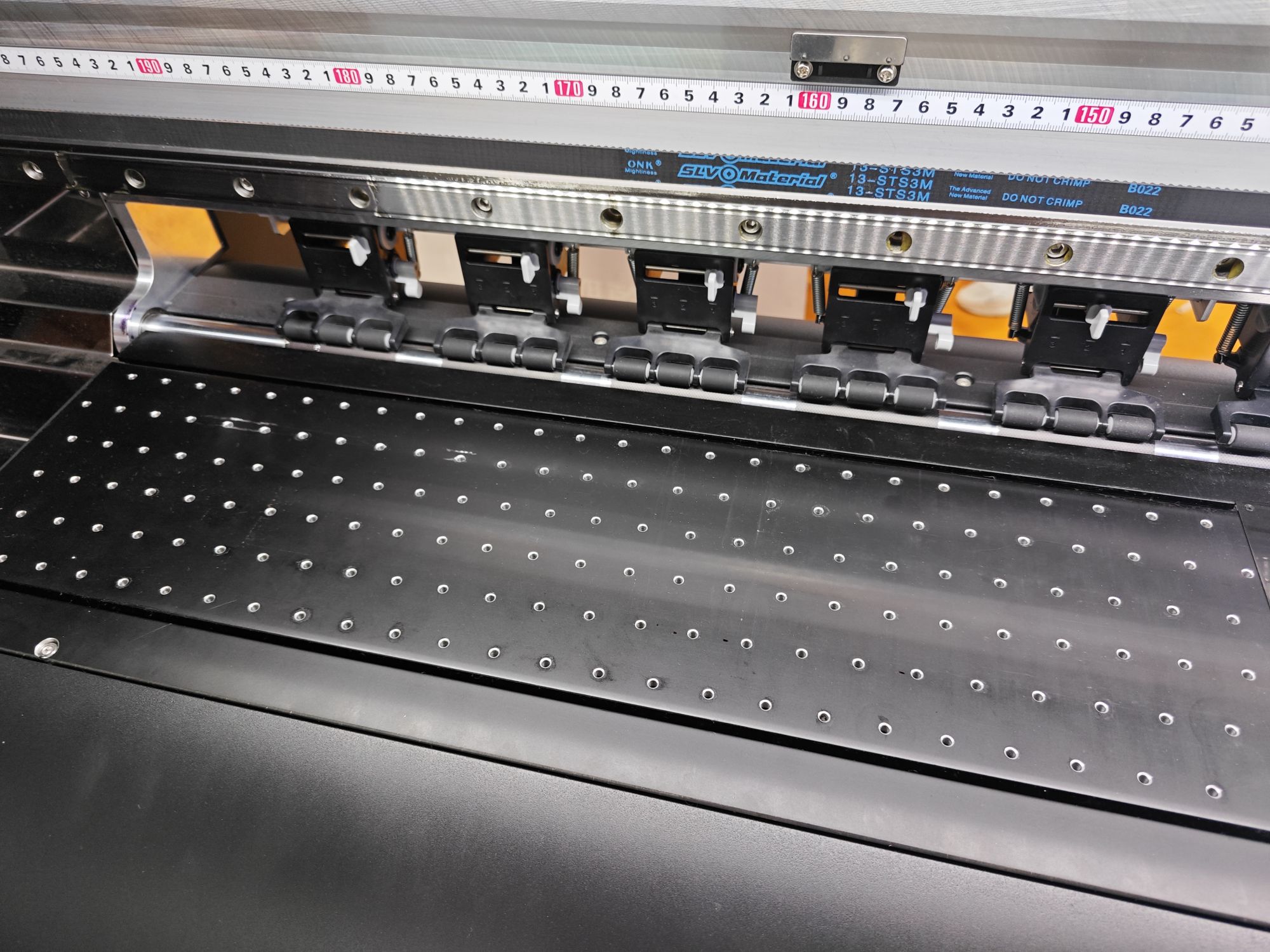

2. Three-Stage Intelligent Media Heating: Control Across the Entire Path

To combat media instability and poor ink adhesion, Fedar wide format printers employ an advanced three-stage intelligent heating system along the media path:

Pre-Print Heating (Front): This stage pre-warms and relaxes the media before it reaches the print zone. It eliminates moisture-induced curling and counteracts thermal contraction, ensuring the material is perfectly flat and dimensionally stable to prevent feeding errors and misalignment.

Print-Zone Heating (Middle): Heating directly under the print area is crucial. It optimizes the ink-substrate bonding process by lowering the ink's surface tension upon contact. This leads to superior color saturation, prevents bleeding or halo effects around edges, and enhances overall color vibrancy.

Post-Print Heating (Rear): Immediately after printing, this stage begins the initial curing process by accelerating solvent evaporation or ink setting. This "pre-drying" step is vital for preventing smudging and prepares the print for final drying, significantly improving the efficiency of the next stage.

3. External High-Power Drying Unit: The Final Touch for Instant Productivity

.jpg)

The final pillar of the system is a powerful external drying unit. This isn't a mere accessory; it's an integrated productivity booster. It provides intense, focused heat to rapidly complete the curing process initiated by the post-print heater. The benefit is game-changing for workflow: prints are ready to handle immediately. You can roll, stack, or process prints right off the printer without fear of ink transfer or smudging. This dramatically reduces job turnaround time, enables back-to-back printing, and is essential for fulfilling high-volume batch orders efficiently during the slow-drying winter months.

Conclusion: Engineered for All Seasons

While winter tests the limits of ordinary printing equipment, Fedar inkjet and wide format printers are engineered to thrive. The integrated synergy of printhead platen heating, the three-stage media heater, and the powerful external dryer creates a controlled micro-climate that nullifies the effects of cold, damp environments. This comprehensive approach ensures that your business maintains peak production efficiency, unmatched print quality, and reliable throughput 365 days a year. Don't let the cold freeze your output—equip your shop with the hardcore heating assurance of a Fedar printer.